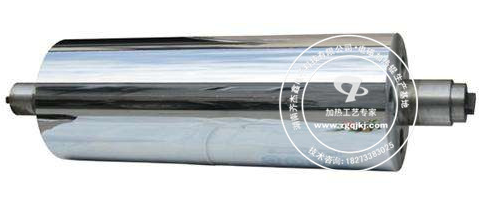

Calendering electromagnetic heating roll -- Application in calendering machine

2, the speed ratio of the roller should be within a certain range, the speed ratio is too large, friction cooked too much, if the export is not timely, will cause rubber burning; If the speed ratio is too small, then the shear action is small, plastic mixing effect is not good, affect the rolling quality. According to practical experience, the rolling speed ratio before forming is generally about 1.3~1.5.

3, in order to ensure the compaction of calendering products, according to the requirements of different materials and products, the rubber should pass through one or more roller spacing.

Calendering electromagnetic heating roll

The main working parts of the roller calendering machine with electromagnetic heating roller directly affect the quality and output of calendering products, so it must have the characteristics of high working surface hardness, wear resistance, sufficient stiffness and hardness, good thermal conductivity, large heat transfer area and high machining accuracy.

Qi Jiexin electromagnetic induction heating roller

An overview of calender

Calendering machine is a kind of precise general rubber machinery. It is mainly used in the rubber industry for gluing film, rubber board, textile and steel curtain cloth. Rubber calender has two rolls, three rolls, four rolls and five rolls, etc., but most of the application is three rolls and four rolls calender, three rolls for sheet, single-side rub or glue, or two in series for double-side adhesive; Four rolls are widely used in tire factories to make double - sided curtain adhesive.

The common calender mainly consists of roller, frame, roller distance adjusting device, roller temperature adjusting device, driving device, lubrication system and control system. In addition to the main parts and devices of the ordinary calender, a device is added to ensure the calender precision.

The working principle of calendering machine is that the plastic material with a certain temperature and plastic degree is fed into two rotating roller, under the action of friction, the plastic material is pulled into the roller distance, due to the gradual decrease of the roller distance section, the plastic material is subjected to a strong extrusion and extended shape. In general, many calendering processes require matching rollers to work at a certain speed ratio to further mix, knead, and increase plasticiability of the compound, and finally, through the minimum roll distance, to be rolled into a film of certain thickness and width. Calender in addition to the rubber material pressed into film, some of the process also needs to be under the effect of the roller extrusion pressure, the film extrusion in the textile (adhesive or rub adhesive) or steel curtain cloth, some need to be pressed into a certain pattern and shape (compression), there is the need to multilayer film adhesive together.

The working conditions

1. The friction Angle between the rubber material and the roller must be greater than the contact Angle of the roller, so that the rubber material can be pulled into the roller distance. Calendering machine in general operation, the roller between the accumulation of less adhesive, and uniform feed, contact Angle is far smaller than the friction Angle, so in general, the rubber can be drawn into the roller distance extension forming.

Widely used in the coated iron, carbon fiber, aramid fiber, lu: su composite, FCCL flexible copper clad, calendering, laser products, print, papermaking, drying, non-woven fabrics and other new materials research and development production, particularly in electromagnetic heating roller coated iron preheating unit, special fibers such as aramid fiber, carbon fiber electromagnetic heating roller drying unit, PI film tensile machine electromagnetic heating roller, copper and aluminum-plastic composite unit temperature process on the solution of the problem, the domestic case, more experienced professional custom heating roller of complete sets of technology solutions. We are willing to work with knowledgeable people from all walks of life to create an efficient, intelligent and environmentally friendly better life.