Methods to Improve the Quality of Flexible Printed Circuit Board——Electromagnetic Heating Roller

作者:管理员 时间:2020-06-04 09:08 来源:未知

浏览:次

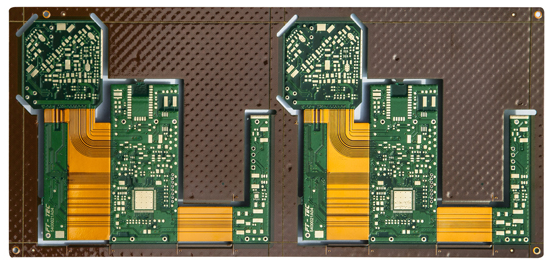

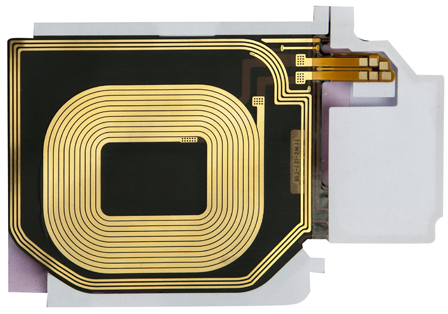

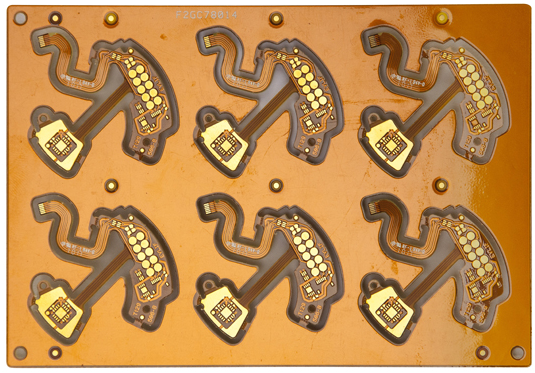

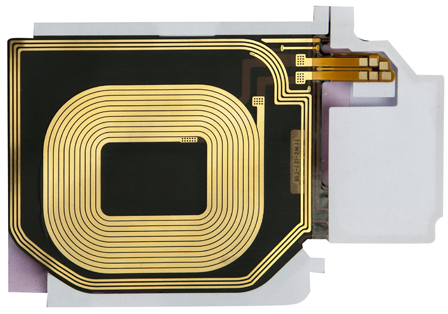

The wide use of flexible board makes this unique circuit material more popular, especially in the production of some electrical components, the performance of flexible circuit board assumes a very important control responsibility. Good circuit control effect and safer operating environment are the significant characteristics of the flexible board itself, which requires higher quality as the premise to ensure better results. Therefore, businesses will improve the quality of flexible circuit board through the following methods.

1:Cut the material according to the specification

Cutting is the head of the FPC PCB raw material production, the quality problem of behind, an important control points, but also the cost of domestic professional flexible circuit board manufacturers in order to control the quality of the circuit board, can ask production personnel equipped with gloves or finger to operation, prevent the oxidation of the copper foil surface due to contact of perspiration, and should be carried out in accordance with the specifications to the material cutting, guarantee the tolerances within the prescribed scope.

2: Drilling in accordance with the specifications

Drilling has a great impact on the subsequent production process of PCB production. In order to ensure the excellent quality of PCB production, flexible circuit board manufacturers will implement the drilling according to the requirements of the code. For example, in the production of a single panel, every 10 to 15 substrates is a stack, double panels are a stack, and three to six reinforcing plates are a stack according to the situation, which can ensure that no deviation occurs during drilling.

3: According to the standard film

Flexible circuit board manufacturers in order to control the quality of the production of circuit board, also requires to follow the specification to film this process. In order to prevent wire breakage during film sticking, clean paper will be used to remove impurities on the surface of copper foil first, and ensure that the direction of copper foil holes in the same direction, at the same time, do not allow operators to directly contact the surface of copper foil, to avoid oxidation of copper foil on the circuit board.

A good design and production plan is an important prerequisite to ensure the production effect, and in order to ensure the use effect and operation quality of this electronic component, the supplier of flexible board will operate in strict accordance with the production process and production requirements. The design quality of this kind of flexible circuit board is fundamentally improved by ensuring the operation methods of cutting and drilling in accordance with its standard mode. The design and effect of this kind of flexible circuit board are guaranteed to a greater extent by referring to a series of production processes.

4. Product screening and use testing.

To ensure the operation effect and operation quality of FPC board must be through a series of screening system to select the high quality products. Therefore, the reasonable price of circuit board manufacturers in the production of this product is a series of strict management attitude, to ensure that the product screening and analysis system has a better effect. And before the factory will also receive a series of professional test to ensure the use of this flexible circuit board quality and use effect is better implemented;

Electromagnetic heating roll (roller) electromagnetic induction heating production base - hunan QiJieXin electronic technology co., LTD. (www.zgqjkj.com/www.qjxdz.com) - electromagnetic heating roller industry for many years engaged in the development of research, successively presided over Guangzhou, Shenzhen, Shanghai, Suzhou, Shenyang, Taiwan, Japan and other regions and countries more than one project design and development, field installation and debugging, mastered all kinds of heating equipment application debugging work performance of electromagnetic heating roller, accumulated a lot of experience. Compared with the products of other companies, the electromagnetic heating roller produced by the company is more intelligent, safe, energy saving and environmental protection, with low maintenance cost, fewer faults and long service life.

3: According to the standard film

Flexible circuit board manufacturers in order to control the quality of the production of circuit board, also requires to follow the specification to film this process. In order to prevent wire breakage during film sticking, clean paper will be used to remove impurities on the surface of copper foil first, and ensure that the direction of copper foil holes in the same direction, at the same time, do not allow operators to directly contact the surface of copper foil, to avoid oxidation of copper foil on the circuit board.

A good design and production plan is an important prerequisite to ensure the production effect, and in order to ensure the use effect and operation quality of this electronic component, the supplier of flexible board will operate in strict accordance with the production process and production requirements. The design quality of this kind of flexible circuit board is fundamentally improved by ensuring the operation methods of cutting and drilling in accordance with its standard mode. The design and effect of this kind of flexible circuit board are guaranteed to a greater extent by referring to a series of production processes.

4. Product screening and use testing.

To ensure the operation effect and operation quality of FPC board must be through a series of screening system to select the high quality products. Therefore, the reasonable price of circuit board manufacturers in the production of this product is a series of strict management attitude, to ensure that the product screening and analysis system has a better effect. And before the factory will also receive a series of professional test to ensure the use of this flexible circuit board quality and use effect is better implemented;

Electromagnetic heating roll (roller) electromagnetic induction heating production base - hunan QiJieXin electronic technology co., LTD. (www.zgqjkj.com/www.qjxdz.com) - electromagnetic heating roller industry for many years engaged in the development of research, successively presided over Guangzhou, Shenzhen, Shanghai, Suzhou, Shenyang, Taiwan, Japan and other regions and countries more than one project design and development, field installation and debugging, mastered all kinds of heating equipment application debugging work performance of electromagnetic heating roller, accumulated a lot of experience. Compared with the products of other companies, the electromagnetic heating roller produced by the company is more intelligent, safe, energy saving and environmental protection, with low maintenance cost, fewer faults and long service life.

Thanks to the efforts of technicians, our electromagnetic heating roller has successfully broken through the high temperature of 500℃, with its surface temperature uniformity of ±1℃ and temperature control accuracy of ±0.1℃, and its long-term stable and reliable performance, which can improve the output and quality of customers' products. The company has been adhering to the "product quality as the life of the enterprise, as the development of science and technology as the soul of the enterprise" purpose, for the company to become the leading force in the industry and struggle!