Hunan JiJieXin electronic technology co., LTD., has

been walking in the forefront of science and technology, provide mobile phone

for shenzhen foxconn motherboard 2013 copper plastic composite boards ready

production equipment, 2014 founded the first in the province, hot-rolled

non-woven production demonstration line for baosteel 2015 domestic only a

independent design + production of food grade coated iron production line, to

break the foreign monopoly, to get the attention of people from all walks of life

in zhuzhou, become the star of the zhuzhou entrepreneurial enterprises, in 2019

in order to expand demand, formal, restructuring for the hunan JiJieXin

electronic technology co., LTD.

Ya-bin liu team: JiJieXin Portland company's core

technology, application of electronic technology professional study 6 years,

who had been sent to communicate with Japanese engineering experts in the field

study, design and manufacturing technology, electromagnetic heating roller

based on independently developed "an intelligent electromagnetic heating

roller and patented, successively presided and participated in the design of:

zhuzhou southern company 608 laser laser anti-counterfeit moulding machine

equipment thermal transfer technology, toyo steel coated iron laminating technology,

foxconn, copper plastic composite board composite technology, baosteel group

coated iron preheating + laminating process design, blue star group of carbon

fiber drawing + + into cloth into plate process design. We are very happy to

cooperate with many enterprises and have been doing business with them for a

long time.

Electromagnetic heating roller (electromagnetic induction heating roller), in the field of material processing practitioners, nine out of ten know the electromagnetic heating roller products. Because a lot of practitioners and business owners in the use of thermal oil roller, steam heating roller and other products in the process of oil leakage, environmental protection, safety, energy consumption of the defects of deep feeling. On the one hand, it is that the temperature uniformity of the heat-conducting oil roller cannot meet the require ments of material production, and it cannot deliver the excellent material products with consistent quality.

The principle of electromagnetic heating roller is simply summarized, that is, the eddy current effect and hysteresis effect of electromagnetic induction are used to make the roller generate heat, the temperature in the working area of the roller surface is uniform by means of uniform temperature, indirect or direct heat exchange is conducted with the processed material , and the temperature is supplemented by a closed loop.

The electromagnetic induction heating roller is widely used in the

research and development and production of new materials such as film coated

iron, carbon fiber, aramide fiber, aluminum-plastic composite, FCCL flexible

copper clad plate, calendering, laser, printing, papermaking, drying, non-woven

cloth and so on.

The need

for masks and protective clothing has increased throughout the world during the

current outbreak. At present, nanometer melt-spraying cloth is the core

material of masks, mainly made of polypropylene. The fiber diameter can reach 1

to 5 microns. The microfiber with unique capillary structure increases the

number and surface area of fibers per unit area, thus making the nanometer melt

spraying cloth have good filtering, air permeability and thermal insulation.

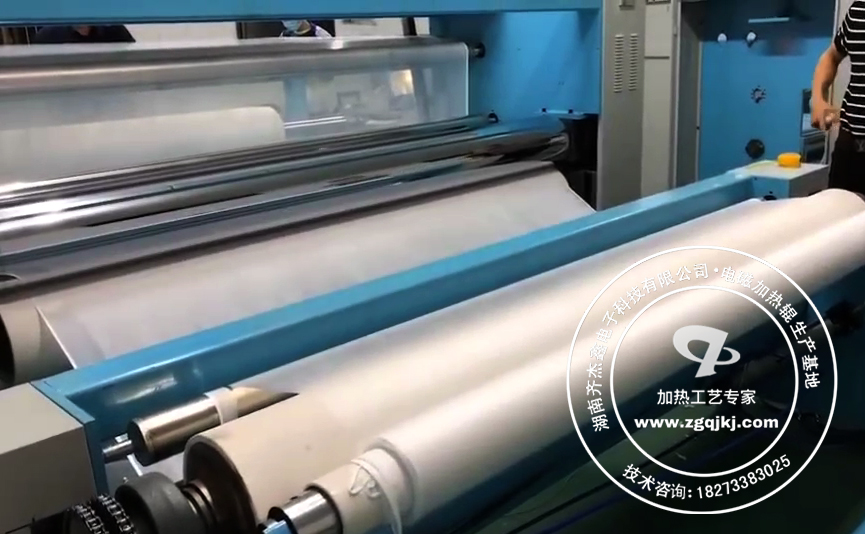

Now many customers choose our company's electromagnetic heating roller production of nano-melt-spraying cloth composite machine.

This nanometer new material trial-produced a new type

of protective KN95 mask to export level. The filtering effect of the new

respirator is better than that of the ordinary one. Its core filter element is

about half of the traditional filter material, and its lighter weight makes it

more comfortable to wear. The picture below shows the products in the field

debugging of 5 electromagnetic heating roller compounding machines that are

currently being delivered -- qijiaxing electronic technology professional

electromagnetic heating roller manufacturer currently our electromagnetic

induction heating roller compounding equipment accounts for 60% of the market

share.