The traditional heat conduction oil heating roller has the disadvantages of oil leakage, uneven temperature, inconvenient maintenance and high energy consumption. Compared with traditional heat conduction oil heating roller, electromagnetic heating roller has several advantages:

1)It can work stably at a temperature of 400℃, breaking through the temperature bottleneck of traditional heat conduction oil and meeting the temperature requirements of high-performance materials. No matter it is high-temperature metal laminating or PTFE compounding with various substrate at high temperature, it can be easily completed;

2) Due to its structural characteristics and excellent performance, the temperature of the roller surface can be kept within ±1℃ when working, and the temperature change curve and gradient can be controlled according to the requirements of special technology, so as to ensure the material quality, reduce the waste products caused by temperature change and improve the yield;

3)Low energy consumption and less maintenance, and remarkable energy saving effect. Compared with the traditional oil temperature machine, the heating assembly power of the electromagnetic heating roller can be reduced by 50% or more, and the complicated heating equipment and pipeline facilities can be abandoned, which can greatly reduce the heating energy consumption.

4) Pollution-free truly realize clean production. Electromagnetic heating roller without heat conduction oil or steam and other heat transfer media, completely eliminate the media leakage, leakage, volatilization caused by pollution and safety hazards, truly achieve dust-free clean production.

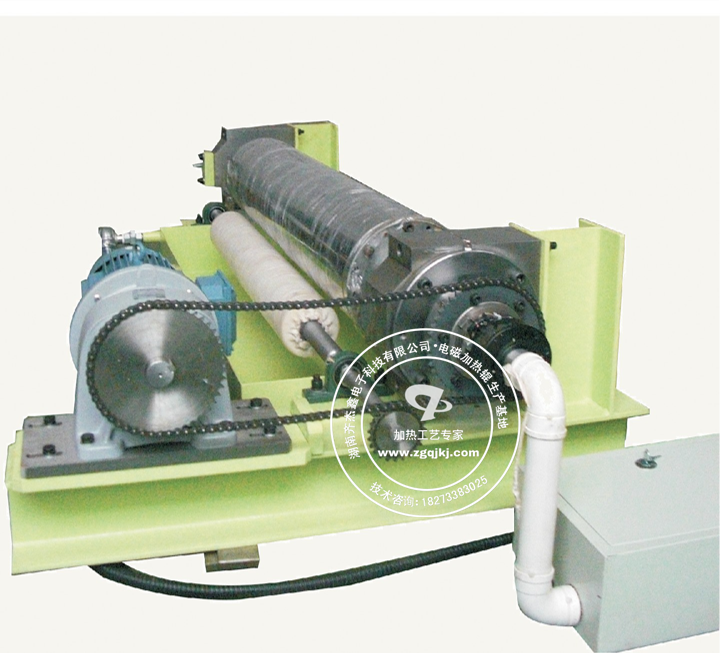

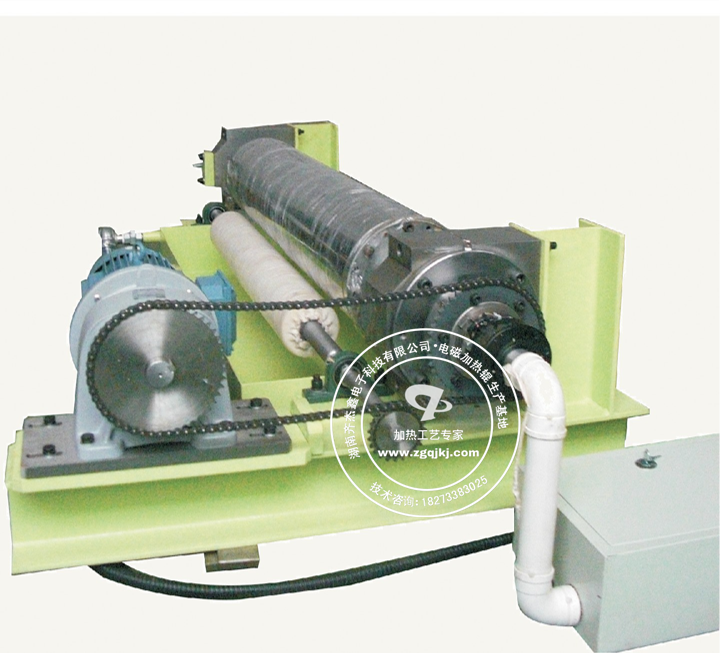

Hunan QiJieXin technology co., LTD. Production of electromagnetic heating roller is widely used in coated iron, carbon fiber,aluminum-plastics compounding, copper plastic composite circuit board (plastic), calendering, plastics, printing, paper making, baking, non-woven fabrics and other new materials research and development production, especially in the effect of preheating unit in ferroelectric magnetic heating roller, aramid fiber, carbon fiber, pbo and other special fiber electromagnetic heating roller drying unit, copper plastic and aluminum-plastic composite electromagnetic heating roller unit to solve temperature problem. Our company is one of the most experienced and professional manufacturers in China. We make outstanding technical contributions to the substitution of domestic brands for imported electromagnetic heating roller.