2. Classification of PI membrane

There are two general categories:

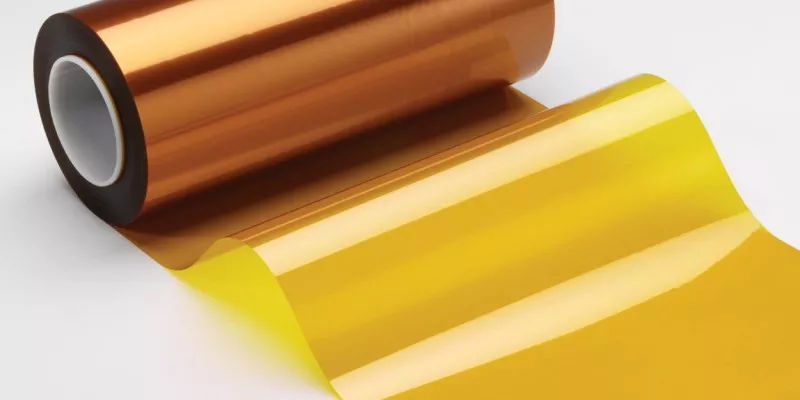

Thermoplastic polyimides, such as imide films, coatings, fibers, and polyimides for modern microelectronics.

Thermosetting polyimides, mainly including bismaleimide (BMI) type and monomer reactant polymerization (PMR) type polyimides and their respective modification products. BMI is easy to process but brittle.

3. Characteristics of PI membrane

(1) excellent heat resistance

Polyimides are generally decomposed at temperatures in excess of 500 ° c and sometimes even higher, making them one of the most thermally stable organic polymers known, mainly because of the large number of aromatic rings in the molecular chains.

(2) excellent mechanical performance

The tensile strength of unreinforced matrix materials is above 100MPa. The tensile strength of Kapton films prepared with homogeneous anhydride was 170MPa, while that of biphenyl polyimide (Upilex S) was 400MPa. Polyimide fibers have an elastic modulus of 500MPa, second only to carbon fiber.

(3) good chemical stability and heat and humidity resistance

Polyimide materials are generally insoluble in organic solvents, resistant to corrosion and hydrolysis. Changing the molecular design can yield varieties with different structures. Some varieties withstand 2 atmospheric pressure, 120℃, 500h of water.

(4) good radiation resistance

The intensity of polyimide film remains 86% after 5×109rad dose radiation, and the intensity of some polyimide fibers after 1×1010rad fast electron radiation remains 90%.

(5) good dielectric properties

Dielectric constant is less than 3.5, if the introduction of fluorine atoms on the molecular chain, dielectric constant can be to around 2.5, the dielectric loss of 10, dielectric strength between 100 and 300 kv/mm, volume resistance is 1015-17 Ω · cm. Therefore, the synthesis of fluorinated polyimide materials is a hot research field.

Hunan JiJieXin electronic technology co., LTD. (www.zgqjkj.com/www.qjxdz.com) -- electromagnetic heating roller production base, specialized in manufacturing of electromagnetic heating heat roll, our mature products now electromagnetic heating roller roller surface temperature of 500 degrees high temperatures, can replace the old heat conduction oil heating roller and the resistance wire heating roller, the saving electricity was above 60%, and roll surface temperature uniformity + / - 1 ℃, the temperature control precision of plus or minus 0.1 ℃. No oil tank, no grease in workshop. Energy conservation and environmental protection, intelligent operation, safe and reliable, improve output, improve product quality, low maintenance cost, fewer faults, long service life.

Is widely used in electromagnetic heating roller coated iron, carbon fiber, lu: su composite, copper plastic composite circuit board (plastic), calendering, plastics, printing, paper making, baking, non-woven fabrics and other new materials research and development production, particularly in electromagnetic heating roller coated iron preheating unit, aramid fiber, carbon fiber, pbo and other special fiber electromagnetic heating roller drying unit, copper plastic and aluminum-plastic composite electromagnetic heating roller unit to solve temperature process problems. Our company is one of the most experienced companies with the most cases of domestic professional manufacturers, and makes outstanding technical contributions to replace the imported electromagnetic heating rollers for domestic brands.