Application of Electromagnetic Heating Roller in Laminating Machine

作者:管理员 时间:2020-06-04 09:07 来源:未知

浏览:次

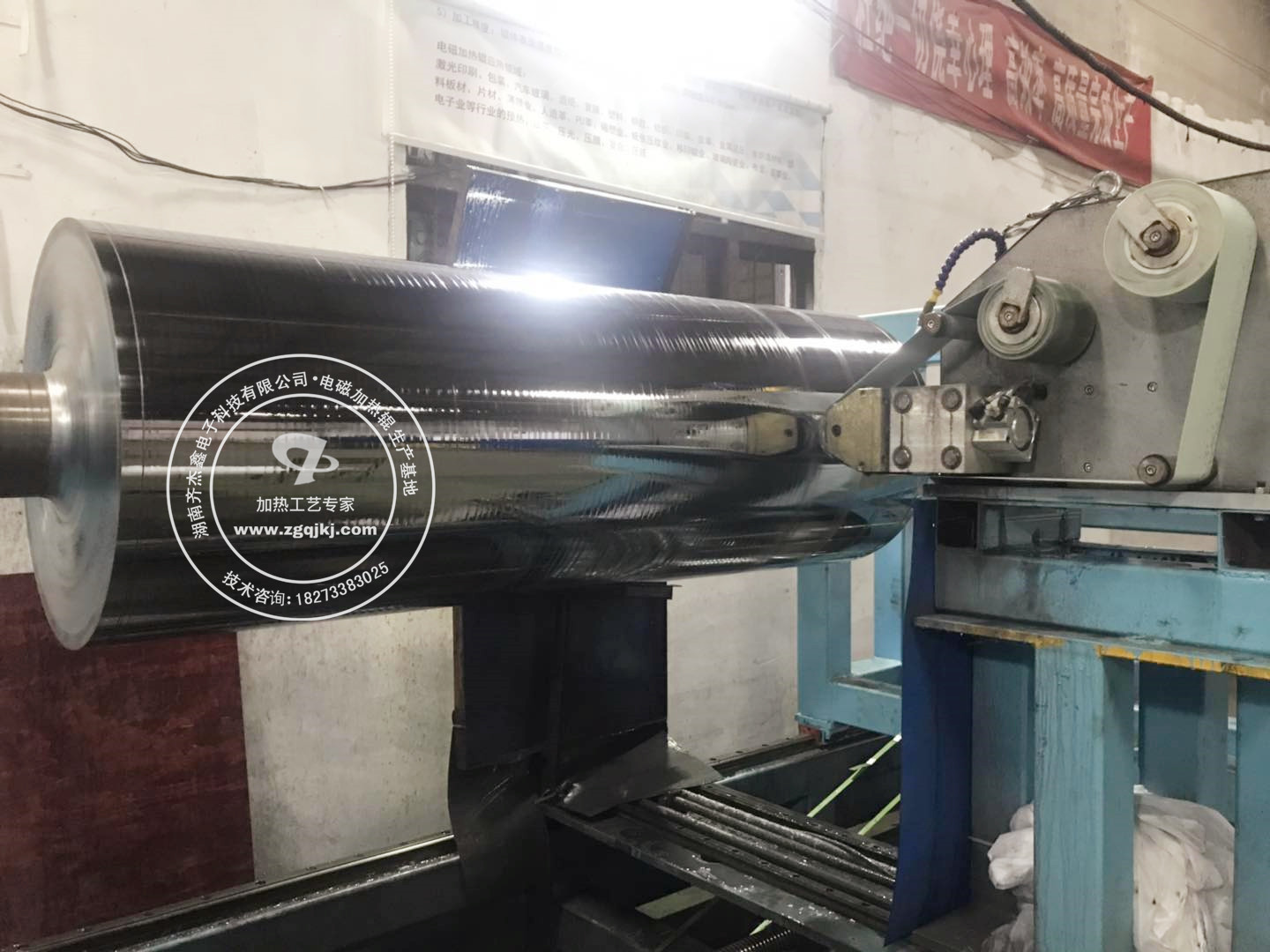

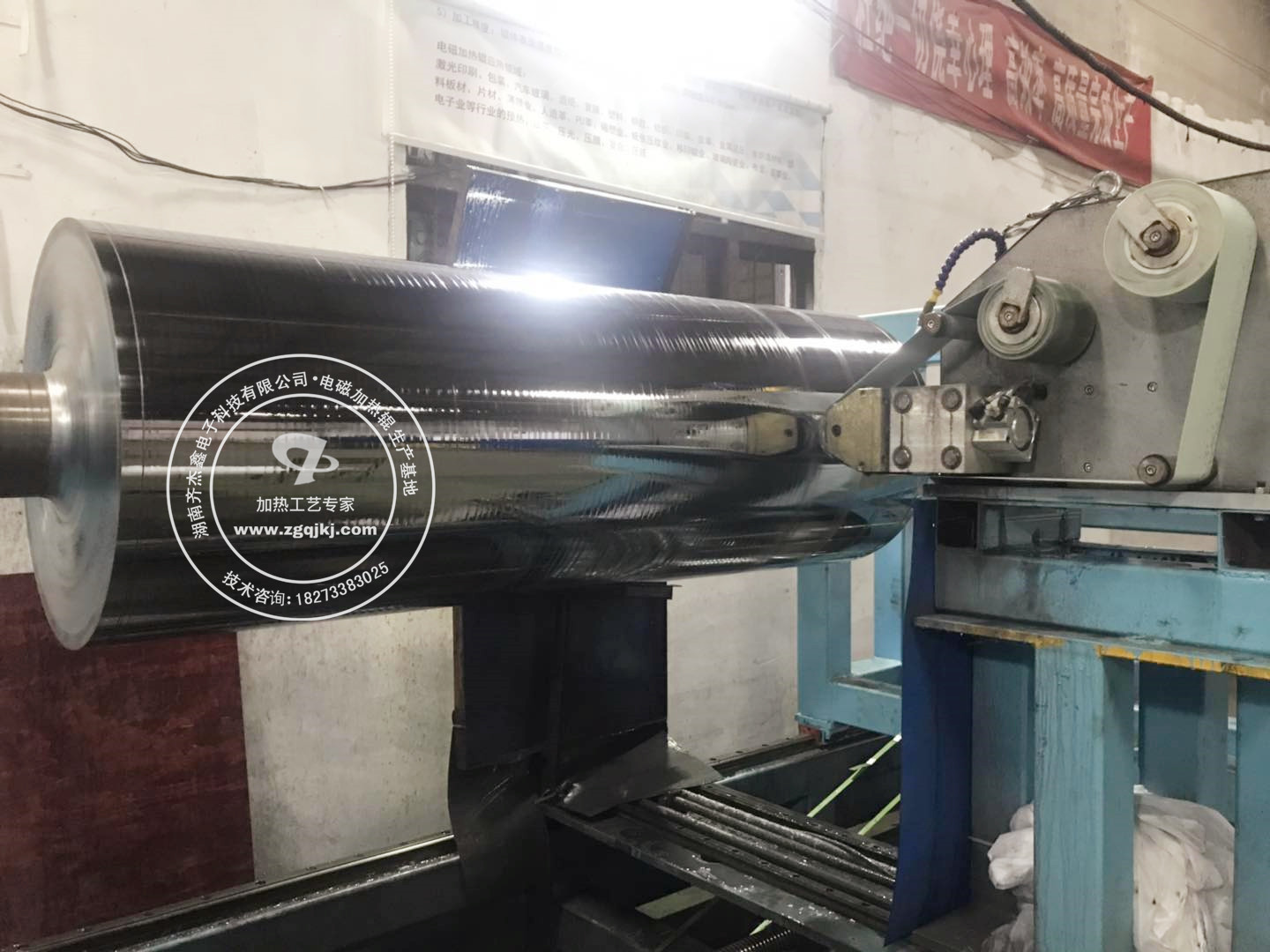

Laminating technology is widely used in our country in all kinds of packaging decoration prints, binding forms of books, books, calendars, maps, etc., is a very popular printing surface processing technology. After laminating printed matter, its wear resistance, flexural resistance, tensile resistance and moisture resistance have been greatly enhanced. Laminating process is divided into coated film and pre-coated film, and pre-coated film in the application of no glue and solvent, is the development trend of safe and environmentally friendly packaging products. Precoating laminating machine is mainly composed of printing input part, hot pressing composite part, transmission system and computer control system. Traditional laminating machine hot pressure summer roll heat conduction oil heating, there are many disadvantages: heat conduction oil in a long time after work, contact with the air will produce carbon structure, and adhere to the inside of the roll, resulting in roller surface temperature due to different wall thickness fluctuations in temperature difference, great impact on the uniformity of laminating; Heat loss is large, heat conversion efficiency is low, so energy consumption is high; Oil leaks and other problems pose a safety hazard. The electromagnetic heating roller makes use of electromagnetic induction to make the roller body heat, without heat conduction oil, eliminating oil leakage and other safety hazards, effectively reducing the production energy consumption. Due to the use of multi-section temperature control, roller surface temperature difference can be controlled within ±1℃, greatly improve the coating uniformity, ensure product quality. Electromagnetic heating roller due to the above high temperature uniformity, energy saving and environmental protection, and other advantages, will become the first choice of laminating machine hot pressure composite roll.

Electromagnetic heating roller is made according to the principle of electromagnetic induction heating metal. Compared with traditional heat-conducting oil heating roller and electric heating roller, electromagnetic heating roller has the advantages of high temperature, good temperature uniformity, easy maintenance, low energy consumption and no pollution. Electromagnetic heating roller can be used in all kinds of pieces of rolling shape, textiles, foaming material of surface pressure light, thin film and all kinds of base material of hot pressing composite, specialty paper and other materials drying and stretching setting and optical anti-counterfeiting laser material extrusion lines, etc., to improve product quality, reduce energy consumption, improve the production environment has good effect.

Japan's electromagnetic heating roller manufacturing technology began to develop in the 1960s, until 2012, its research and development, manufacturing technology has been relatively mature, in the world's leading position. Because electromagnetic heating roller manufacturing involves material, chemical, mechanical, automatic control, electronics and other disciplines of professional knowledge, manufacturing difficulty is high, so although after decades of development, the technology is still only a few enterprises to master. The electromagnetic heating roller used in domestic high-end industries was mainly made by Japanese products, which was expensive and inconvenient to maintain, resulting in high production costs. At the beginning of the 21st century, some domestic enterprises began to develop electromagnetic heating roller technology. After ten years of development, some enterprises in zhuzhou, hunan have successfully mastered the core technology of electromagnetic heating roller independently developed and successfully applied in the commercial field.