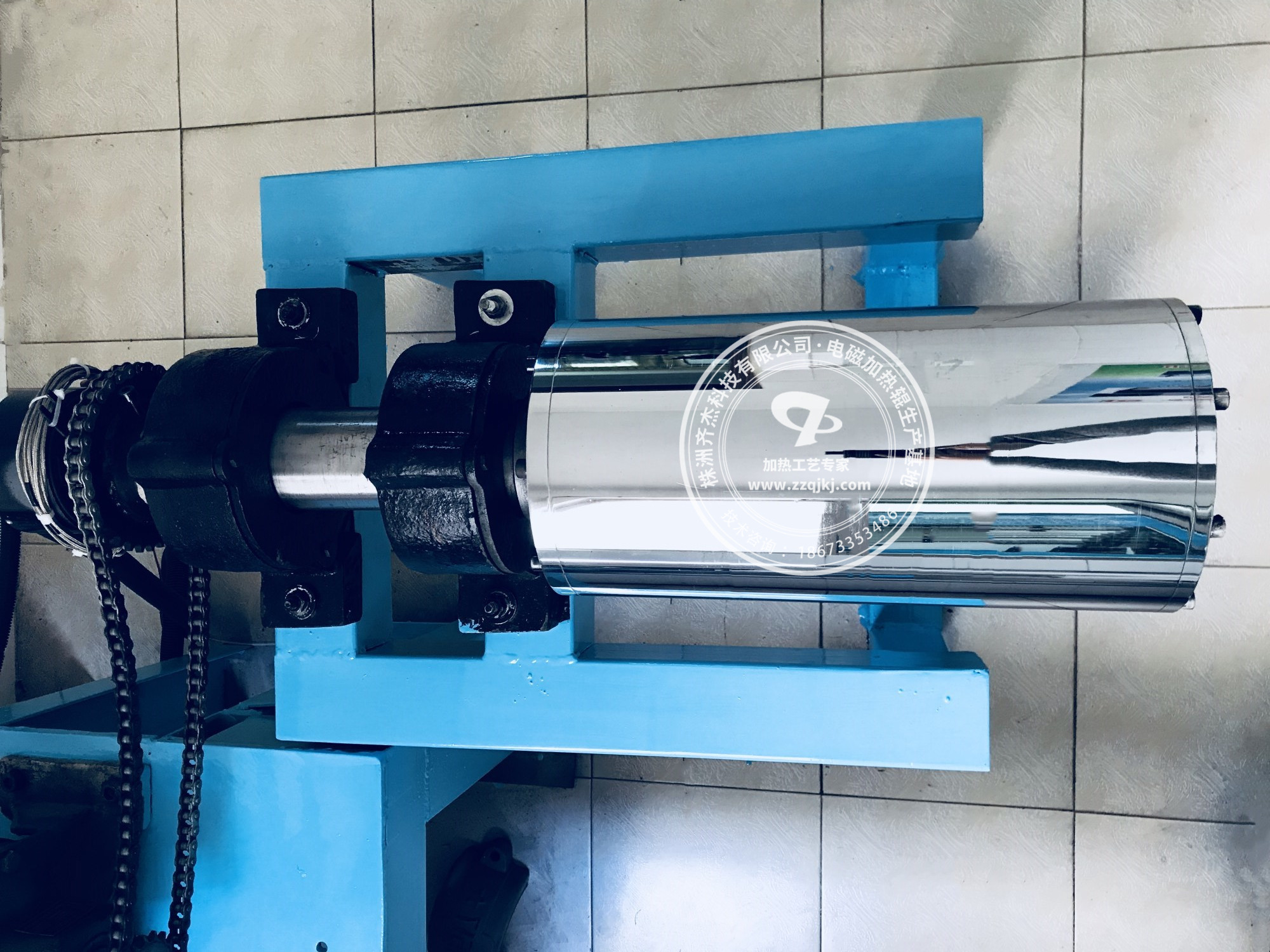

Single wall suspension electromagnetic heating roller Common specifications: 200mm, 600mm, L400mm to L4000mm, and can be customized according to customer requirements. The surface temperature is 100 to 550 degrees, and can be customized according to customer requirements. Roll body speed: 100 ~ 800m/min; Linear pressure: 0 ~ 20kg/m;