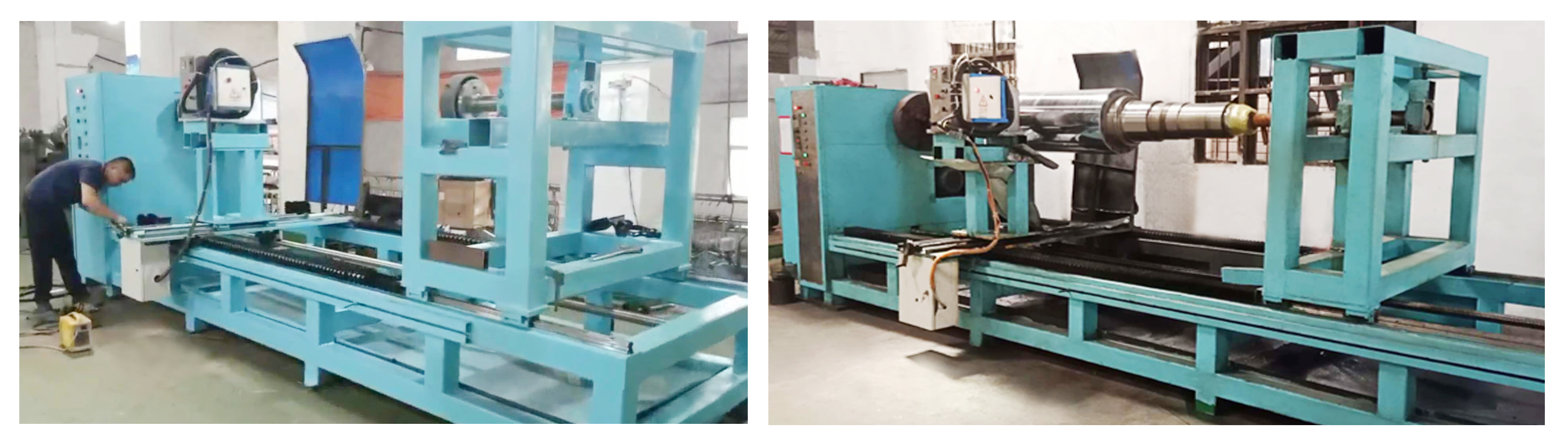

1. The maximum polishing diameter reaches 1500CM and the length can be processed 4500CM. However, the maximum polishing diameter of the mirror polishing equipment of the traditional mirror machine cannot exceed 600cm, which is a relatively large mirror machine at present.

2. Our mirror machine equipment adopts automatic control mode, with intuitive and convenient operation interface, program control and simple operation. Comprehensive security considerations. Real-time monitoring, fault error alarm, easy maintenance.

3. Its single side mirror polishing time is controlled uniformly and fixed, which can ensure the mirror uniformity of the product.

Advantage: Precise control of mm polishing time and the mirror effect of the surface

Application advantages: high quality, high efficiency, economy, environmental protection, safety